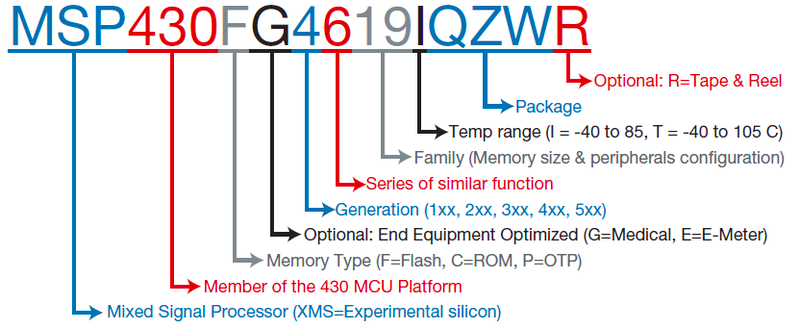

Part Numbering System Best Practices

Part numbering system best practices. ITs dumb fight over intelligent part numbers. Rather than become caught up in the numbering focus on who owns the documentation the document control process and the method by which documents are created as new processes come into play. Iii DESCRIPTION OF REVISION This revision which supersedes the Goddard Space Flight Center GSFC Standard X-673-64-1E Engineering Drawing Standards Manual is intended to update and reflect the latest formats and standards adopted by GSFC.

But neither should you continue assigning new numbers within an old system that is not working. Heres what we suggest for a company to use on their cadpart numbering system that will provide minimum friction and maximum flexibility. I started working as an apprentice one year before I went to university.

A PLM tools part numbering capacities can make it easy to centralize the Part Numbering System prevent conflicts with external part numbers as well as navigate multiple Bills of Materials. The One True Part Number System. Read this article to learn what it takes to get started and how Arena PLM can support either type of part numbering system.

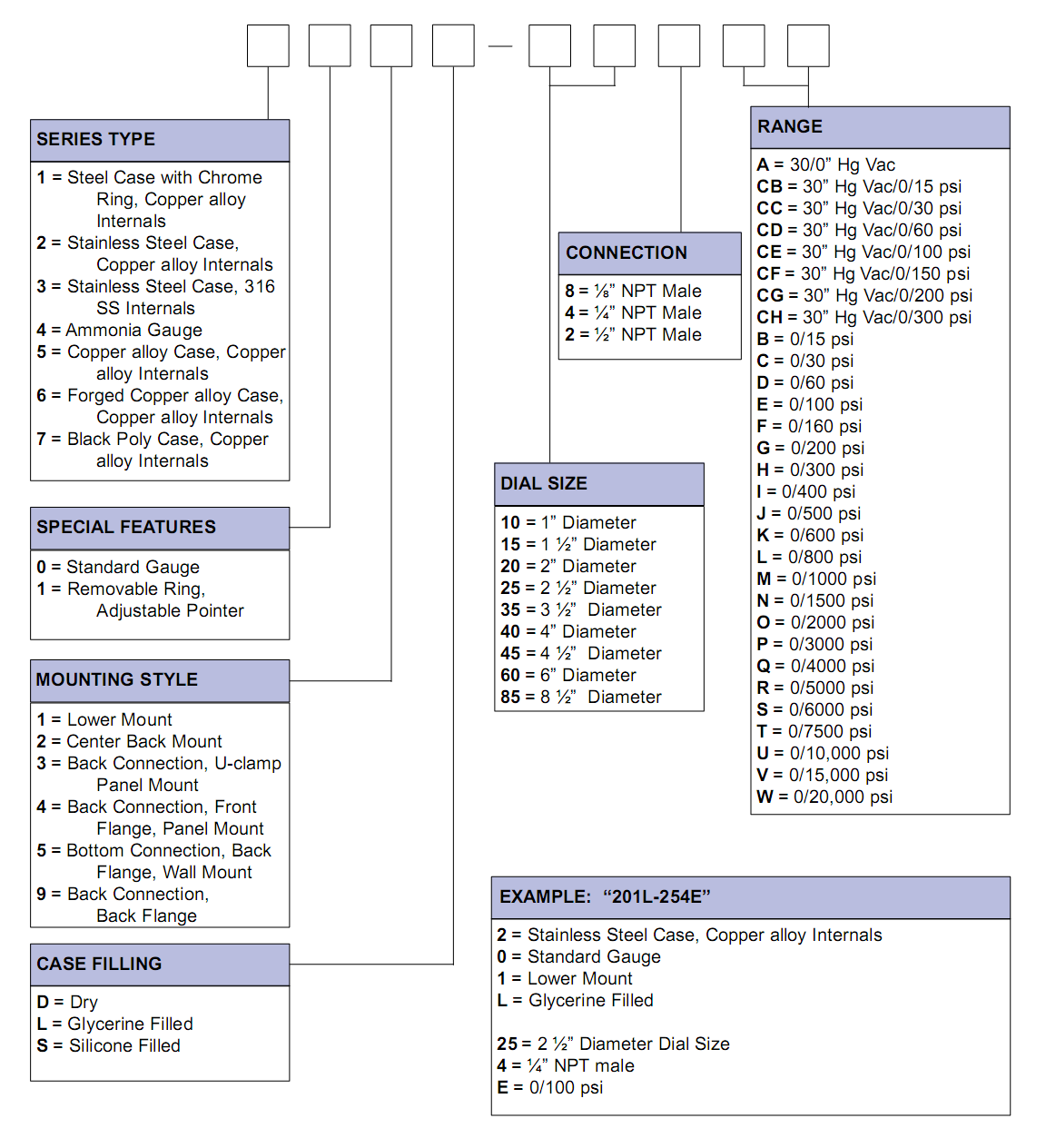

I recently started a position at a company with only one other engineer. But if you wish here is an example of a system that I devised many years ago and has its origin in the DOS days. This was the first time I held a real drawing in my hands and it had a real drawing number on it too.

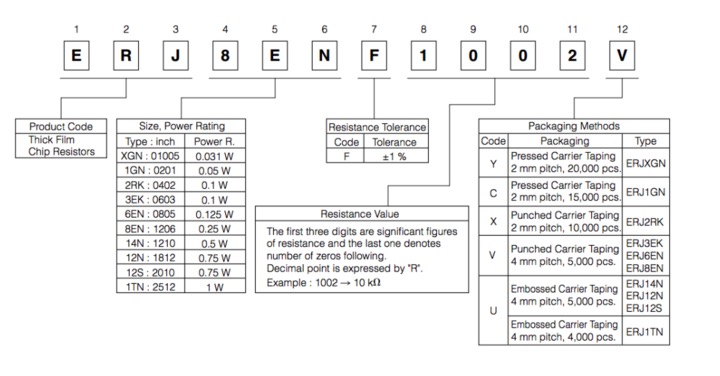

Using this part numbering system a resistor could be assigned part number 000416782. I have worked in companies with both extremes of part numbering systems and at a few of them I have been there when they set them up. I have never had to create one on my own Thank you.

As others have pointed out - and as youve realized - things change organizations evolve and so too does the documentation. Part numbering schemes. Ultimately a PLM-based Part Numbering System is the emerging industry best practice for centralizing part numbering across teams tools and avoiding costly downstream issues for ERP or IMS.

1234-9999 is followed by 1235-0000. The part number does not provide any information about the part.

Iii DESCRIPTION OF REVISION This revision which supersedes the Goddard Space Flight Center GSFC Standard X-673-64-1E Engineering Drawing Standards Manual is intended to update and reflect the latest formats and standards adopted by GSFC.

This was the first time I held a real drawing in my hands and it had a real drawing number on it too. The part number does not provide any information about the part. The One True Part Number System. The battle pits intelligent numbering. Sequential Part Number System. Heres what we suggest for a company to use on their cadpart numbering system that will provide minimum friction and maximum flexibility. Originally Posted by sniper1rfa Sooner or later probably sooner rather than later youre going to have something which needs a part number but doesnt fit into your system at which point youre totally fucked. Iii DESCRIPTION OF REVISION This revision which supersedes the Goddard Space Flight Center GSFC Standard X-673-64-1E Engineering Drawing Standards Manual is intended to update and reflect the latest formats and standards adopted by GSFC. ITs dumb fight over intelligent part numbers.

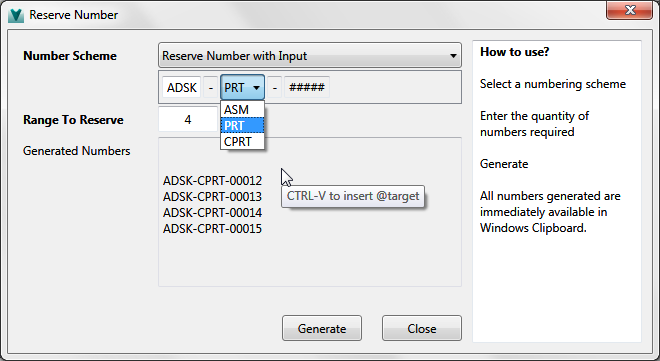

Do what makes most sense for your company and its document user community. Non-significant part numbers are typically serial pulled in numerical order regardless of the type of part. All Other Docum A document numbering system is not required. Up to this point no part numbering system has been used. Sequential Part Number System. In a battle as old as ERP itself users demand intelligent numbers that the IT team bucks against. This was the first time I held a real drawing in my hands and it had a real drawing number on it too.

Post a Comment for "Part Numbering System Best Practices"